What is a Cable Harness? Exploring Its Role in Modern Connectivity and Industry Applications

In the rapidly evolving landscape of modern connectivity, the significance of cable harnesses cannot be overstated. A cable harness, which serves as a network of wires, connectors, and terminals, plays a crucial role in a wide array of industries, including automotive, aerospace, and electronics. According to a recent report by Grand View Research, the global cable harness market is projected to reach USD 210.7 billion by 2025, driven by increasing demand for automated and efficient connectivity solutions. As technological advancements persist, cable harnesses are becoming increasingly sophisticated, offering enhanced durability and reliability in even the harshest environments. In this exploration, we will delve into the multifaceted applications of cable harnesses, highlighting their essential contributions to modern innovation and industrial functionality.

The Definition of Cable Harness: Understanding Its Components and Structure

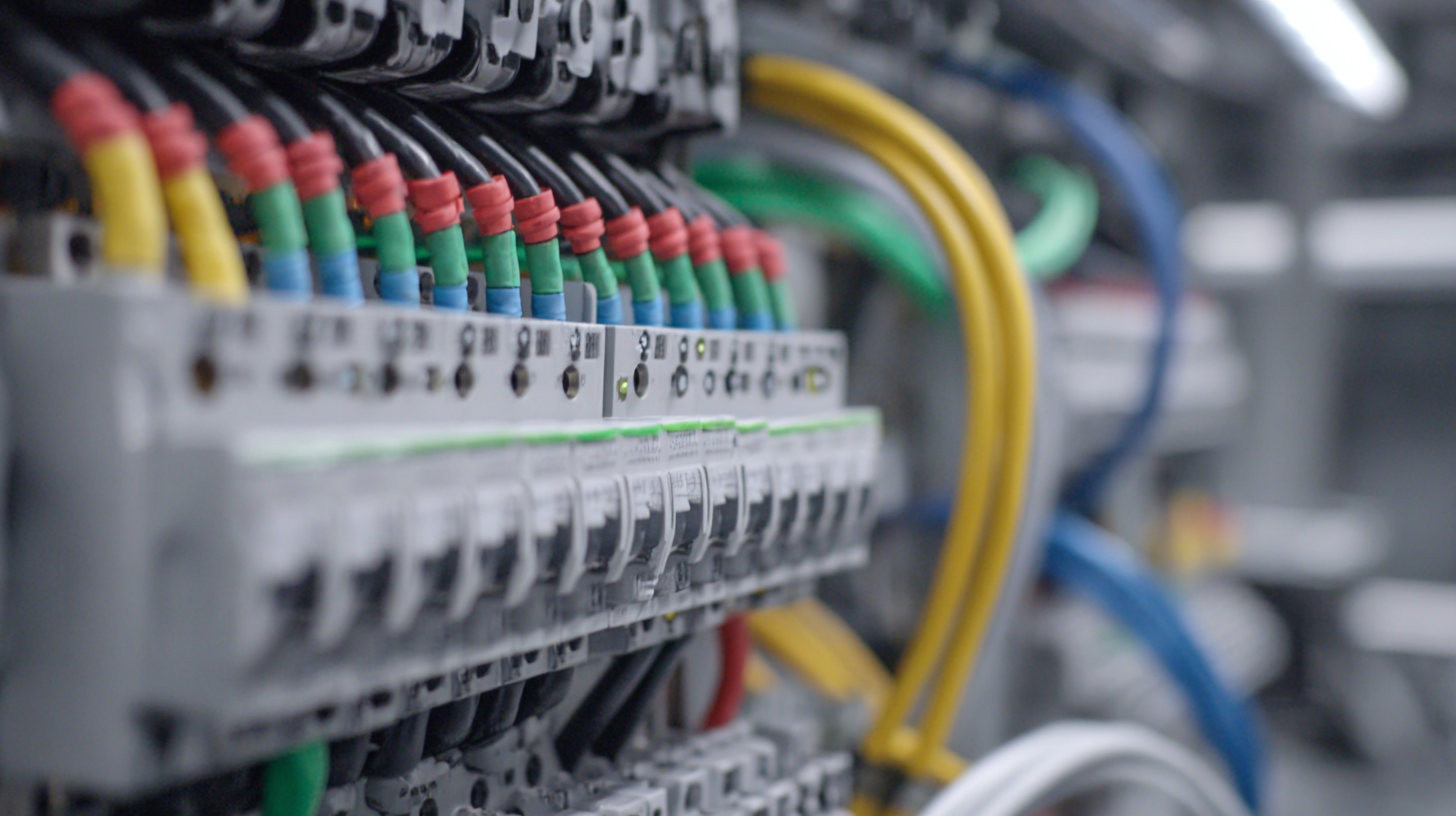

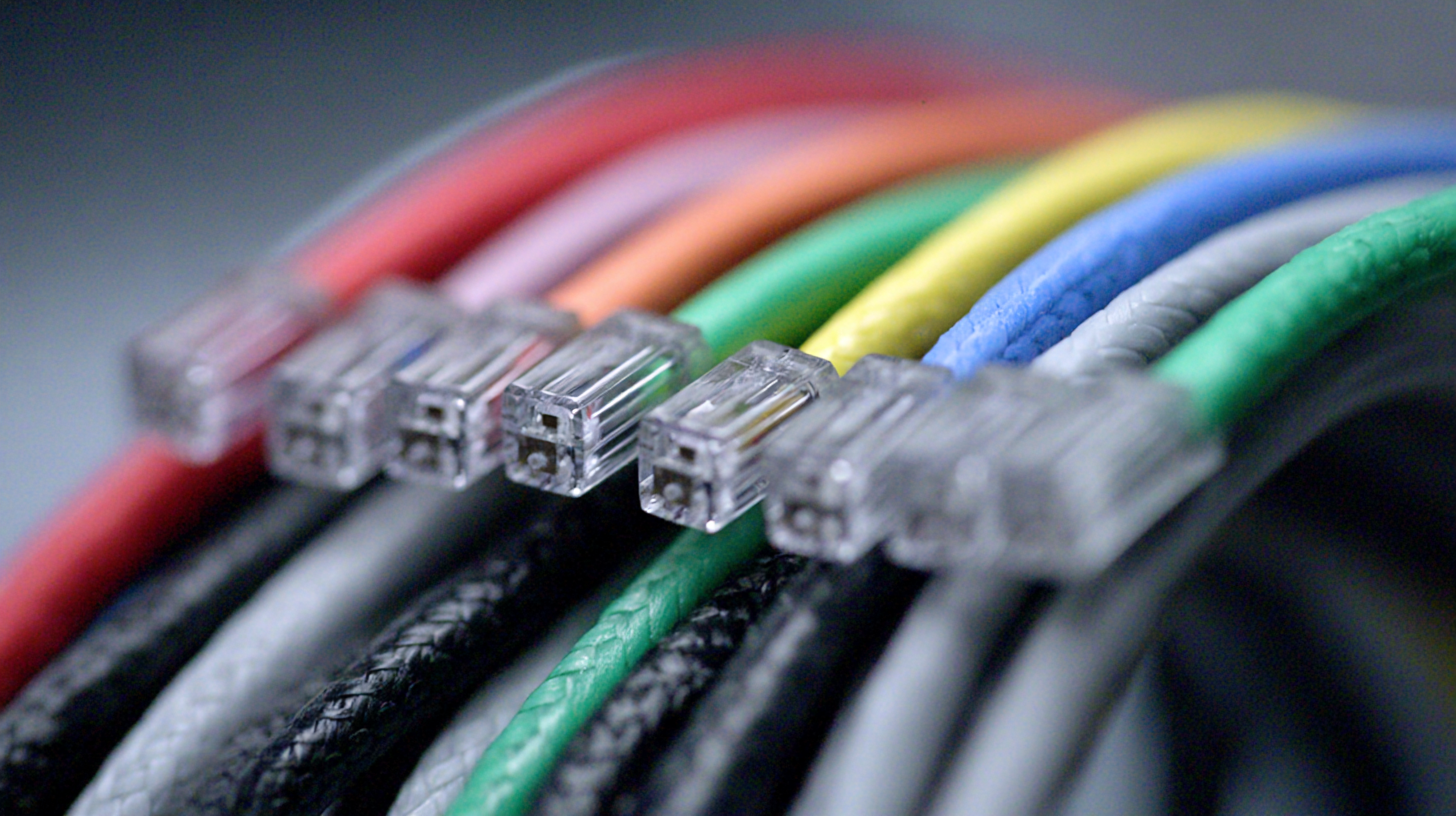

A cable harness, often referred to as a wiring harness, is a critical assembly of electrical cables or wires that transmit signals and power between various components in a system. Typically, a cable harness consists of multiple wires, connectors, and junctions grouped together to form a single unit that simplifies the complex wiring in devices. Depending on the industry, the components of a cable harness can vary significantly, including factors such as insulation material, gauge size, and the types of connectors used, all tailored to meet specific performance requirements.

Industry reports indicate a rising demand for cable harnesses in sectors such as automotive, aerospace, and telecommunications. According to a recent market analysis by Grand View Research, the global wiring harness market is projected to reach USD 83.7 billion by 2025, driven by increasing automation in various industries and advancements in connectivity technologies. The growing need to streamline electrical systems and enhance reliability has led manufacturers to innovate in areas like lightweight materials and improved design methodologies, ensuring that these harnesses can support modern technological demands effectively.

The Growing Market for Cable Harnesses: Industry Trends and Forecasts

The cable harness market is experiencing significant growth, driven by advancements in technology and increased demand across various industries. According to a recent report by Allied Market Research, the global cable harness market was valued at approximately $39.0 billion in 2020 and is projected to reach around $66.0 billion by 2027, growing at a compound annual growth rate (CAGR) of 8.1% during the forecast period. This growth is being fueled by the rise of automotive electronics, aerospace applications, and the expanding telecommunications sector.

In the automotive industry, the shift towards electric vehicles (EVs) has particularly impacted the demand for cable harnesses. A report by Research and Markets indicates that the automotive segment alone is expected to hold the largest share of the market, as vehicles become increasingly reliant on complex wiring systems for safety features and infotainment systems. Furthermore, the proliferation of smart homes and connected devices is propelling growth in the consumer electronics sector, with cable harnesses playing a critical role in ensuring reliable connectivity and performance. As industries continue to innovate, the versatility and efficiency of cable harnesses will remain crucial in meeting the challenges of modern connectivity.

What is a Cable Harness? Exploring Its Role in Modern Connectivity and Industry Applications - The Growing Market for Cable Harnesses: Industry Trends and Forecasts

| Application Sector | Market Size (Million USD) | Growth Rate (% CAGR) | Key Drivers |

|---|---|---|---|

| Automotive | 29,000 | 7.5 | Increase in electric vehicles and advanced safety features |

| Aerospace | 11,500 | 6.2 | Demand for lightweight and durable materials |

| Industrial Machinery | 15,000 | 5.5 | Automation and Industry 4.0 initiatives |

| Telecommunications | 27,000 | 8.0 | Expansion of 5G networks and broadband demand |

| Consumer Electronics | 20,000 | 4.8 | Increasing smart device adoption |

Key Applications of Cable Harnesses in Automotive and Aerospace Industries

Cable harnesses play a pivotal role in modern technology, especially in the automotive and aerospace industries. In automotive applications, cable harnesses are integral for connecting various electrical components, from the engine management system to infotainment and safety features. These harnesses streamline wiring, reduce the risk of short circuits, and simplify assembly, making them essential for enhancing vehicle reliability and performance. By organizing and securing multiple wires within a single assembly, they not only save space but also facilitate maintenance and troubleshooting.

Cable harnesses play a pivotal role in modern technology, especially in the automotive and aerospace industries. In automotive applications, cable harnesses are integral for connecting various electrical components, from the engine management system to infotainment and safety features. These harnesses streamline wiring, reduce the risk of short circuits, and simplify assembly, making them essential for enhancing vehicle reliability and performance. By organizing and securing multiple wires within a single assembly, they not only save space but also facilitate maintenance and troubleshooting.

In the aerospace sector, cable harnesses are critical for ensuring the safety and reliability of aircraft systems. They are designed to withstand extreme conditions, including high temperatures and vibrations, which are common during flight operations. Aerospace cable harnesses connect critical systems such as avionics, navigation, and communication equipment, ensuring seamless operation and communication between these systems. The use of advanced materials and technologies in their design enhances their durability and performance, which is paramount in the highly regulated aerospace industry. Thus, the importance of cable harnesses cannot be overstated, as they are essential for advancing connectivity and safety in both sectors.

Innovations in Cable Harness Design: Enhancing Efficiency and Reducing Costs

Innovations in cable harness design have become pivotal in enhancing efficiency and reducing costs across various industries. According to a report by MarketsandMarkets, the global cable harness manufacturing market is projected to reach $82.6 billion by 2025, growing at a CAGR of 5.6%. This growth is driven by the rising demand for integrated solutions in sectors like automotive, aerospace, and industrial automation.

Modern cable harness designs leverage advanced materials and manufacturing techniques, enabling significant weight reductions without compromising reliability. For example, the use of lightweight composite materials can lead to a reduction of up to 25% in weight compared to traditional options.

Modern cable harness designs leverage advanced materials and manufacturing techniques, enabling significant weight reductions without compromising reliability. For example, the use of lightweight composite materials can lead to a reduction of up to 25% in weight compared to traditional options.

Tips: When selecting a cable harness for your project, consider not only the material specifications but also the harness’s design flexibility. Modular designs allow for easier upgrades and modifications, making your systems future-proof.

Furthermore, innovations such as 3D printing and automated assembly systems are revolutionizing the cable harness industry. These technologies enable manufacturers to produce more complex and customized harnesses efficiently. A report from Research and Markets highlights that automation in production processes can decrease manufacturing costs by approximately 30%. Such improvements not only reduce lead times but also enhance overall product quality, ensuring that industries can meet increasing performance demands while keeping costs in check.

Tips: Opt for suppliers that incorporate advanced technologies in their harness manufacturing. This can significantly affect the longevity and performance of the cable harness in real-world applications.

The Importance of Quality Testing and Certification in Cable Harness Production

In the realm of modern connectivity, the production of cable harnesses plays a crucial role in various industrial applications, from automotive to telecommunications. With the increasing complexity of electronic devices, ensuring the reliability and efficiency of these cable systems is paramount. Quality testing and certification serve as the backbone of this assurance, as they not only validate performance but also help to prevent costly failures in high-stakes environments. According to industry reports, about 30% of product failures are attributed to poor quality in cable assemblies, underlining the need for stringent quality control measures.

To maintain high standards in cable harness production, manufacturers must adhere to specific testing protocols. For instance, tests such as tensile strength, insulation resistance, and thermal cycling are essential to ensure that a cable harness can withstand harsh conditions. The International Electrotechnical Commission (IEC) states that over 40% of electrical safety issues arise from untested or insufficiently tested components. Implementing comprehensive quality checks significantly reduces risks and enhances the overall longevity of the products.

Tips for manufacturers include investing in advanced testing equipment and training staff on the latest quality assurance protocols. Additionally, collaborating with accredited certification bodies can streamline the compliance process and strengthen market positioning. Emphasizing quality testing not only helps meet regulatory standards but also fosters customer trust and satisfaction, crucial elements for success in today's competitive landscape.

Related Posts

-

5 Essential Reasons Your Business Needs a Reliable Cable Harness Supplier

-

Challenges Faced in Cable Harness Design Efficiency

-

Innovative Applications of Molded Cable Assemblies Across Various Industries

-

What is a Cable Wire Harness and How Does It Power Modern Innovations?

-

How to Optimize Your Electrical Harness Assembly for Maximum Efficiency

-

How to Select the Right Electrical Harness Connectors for Your Projects